Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Tel: +86 188 2689 9458

Time:2025-11-05 Views:

Introduction

In the dynamic realm of liquid packaging, finding the right solution is crucial for businesses across various industries. Whether it's transporting food-grade liquids like wine and edible oils or handling industrial fluids such as lubricants and non - hazardous liquid chemicals like surfactants, the packaging plays a vital role in ensuring product integrity, safety, and cost - effectiveness. Among the numerous packaging options available, the Paper IBC (Intermediate Bulk Container) has emerged as a game - changer. It combines the best of both worlds: the strength and versatility required for industrial applications and the environmental friendliness that aligns with the growing global focus on sustainability. In this article, we will delve deep into the advantages of Paper IBCs, and also shed light on why choosing a reliable PAPER IBC manufacturer like Topline can make all the difference for your liquid packaging needs.

What is Paper IBC?

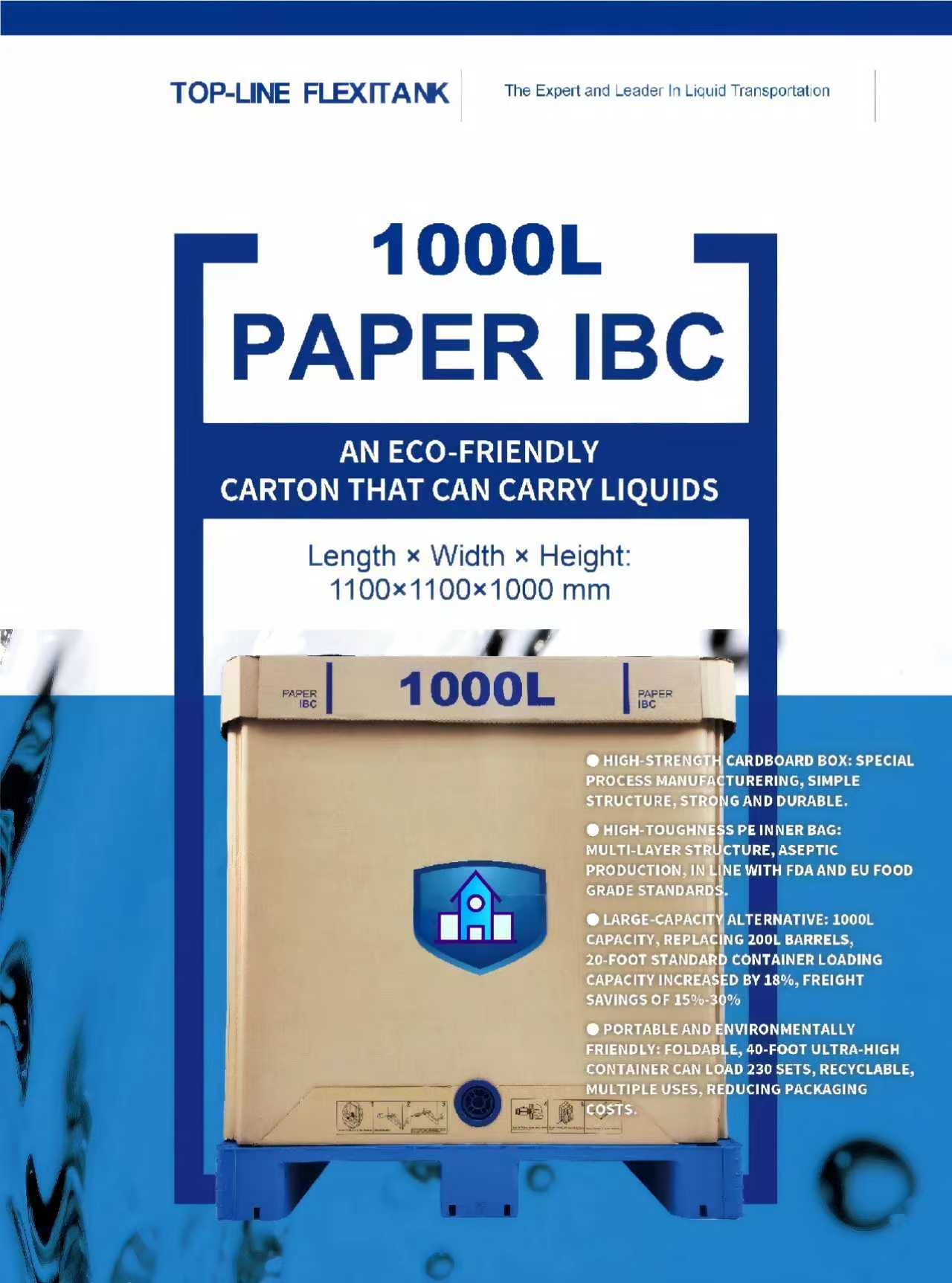

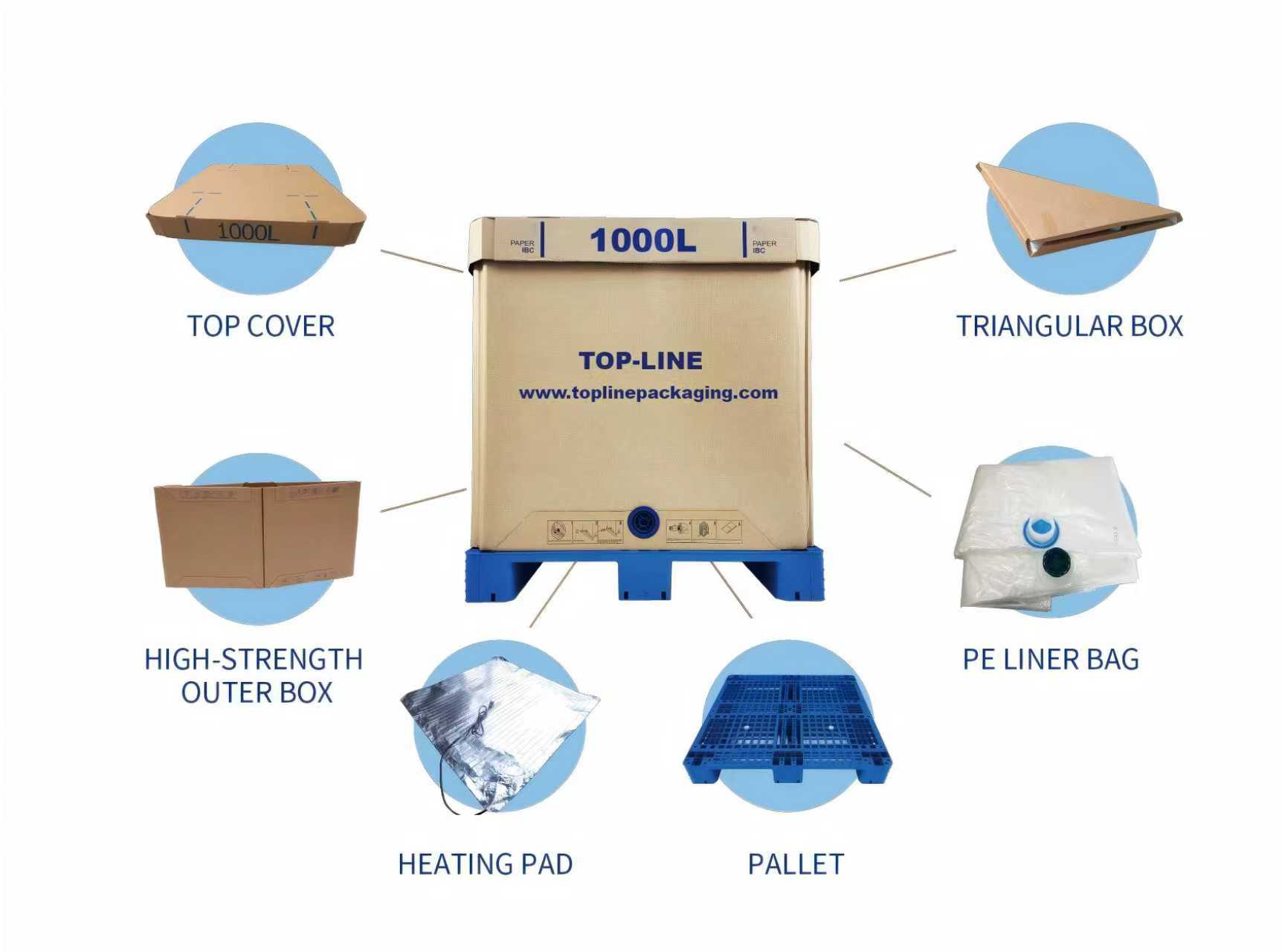

Definition and Structure

A Paper IBC, or Intermediate Bulk Container, is a specialized packaging solution designed for the storage and transportation of liquids. It is composed of a combination of a high - strength cardboard structure and a high - toughness multi - layer PE inner bag or a sterile bag. The cardboard provides the outer shell, offering structural integrity and protection against external impacts. It is engineered to withstand the rigors of handling during storage and transportation. The multi - layer PE inner bag, on the other hand, comes into direct contact with the liquid. The multiple layers of the PE inner bag are designed to prevent leakage, ensuring the safety of the liquid product. In the case of food - grade applications, a sterile bag might be used to maintain the hygiene and quality of the liquid, such as in the packaging of wines or edible oils.

Working Principle

The working principle of a Paper IBC is straightforward yet highly effective. When it comes to storing liquids, the liquid is poured into the inner bag through a specially designed inlet. The multi - layer structure of the inner bag, whether it's a PE inner bag or a sterile bag, acts as a barrier. It prevents the liquid from seeping out and also protects it from external contaminants. During transportation, the robust cardboard structure of the Paper IBC safeguards the inner bag and its contents. The cardboard can endure the forces exerted during loading, unloading, and transit, whether it's on a truck, ship, or train. When it's time to dispense the liquid, there is usually an outlet valve or spout attached to the inner bag, which allows for controlled and convenient release of the liquid, making it suitable for a wide range of industrial and food - grade liquid handling needs.

Applications of Paper IBC

Food Industry

In the food industry, Paper IBCs have found extensive applications. For the packaging of wines, their ability to maintain a sterile environment is crucial. The sterile inner bags of Paper IBCs prevent any external contaminants from entering, ensuring the wine's quality and flavor are preserved. This is especially important for high - end wines that require strict storage conditions during transportation. When it comes to edible oils, Paper IBCs offer a cost - effective and reliable solution. The multi - layer PE inner bag effectively prevents oil leakage, and the cardboard structure provides protection during handling. This makes it easier for edible oil manufacturers to transport large volumes of their products safely, whether it's for domestic distribution or international exports.

Industrial Oils

In the realm of industrial oils, Paper IBCs are widely used for packaging lubricants, glycerol, and high - oil fatty acids. Lubricants, which are essential for machinery operation, need to be transported without any risk of contamination or leakage. Paper IBCs' high - strength cardboard and leak - proof inner bags ensure that lubricants reach their destination in optimal condition. Glycerol, used in various industrial processes such as the production of cosmetics and pharmaceuticals, also benefits from the protective packaging of Paper IBCs. Their ability to maintain the purity of glycerol during storage and transportation is highly valued by industries that rely on its quality. High - oil fatty acids, which are used in the manufacturing of soaps and detergents, can be efficiently stored and transported in Paper IBCs, making them a preferred choice for the industrial oil sector.

Non - Hazardous Liquid Chemicals

For non - hazardous liquid chemicals like surfactants, synthetic resins, and synthetic latex, Paper IBCs provide an ideal packaging solution. Surfactants, which are used in products such as detergents and personal care items, require packaging that can prevent evaporation and maintain their chemical properties. The tight - sealing inner bags of Paper IBCs meet this requirement. Synthetic resins, which are used in the production of plastics and adhesives, and synthetic latex, used in the manufacturing of paints and coatings, can be safely stored and transported in Paper IBCs. Their robust structure and chemical - resistant inner bags ensure that these non - hazardous liquid chemicals can be handled with ease throughout the supply chain, from production facilities to end - users.

Advantages of Paper IBC Containers for Sea Packaging Bags

Cost - Effective

One of the primary advantages of Paper IBCs is their cost - effectiveness. Firstly, compared to traditional packaging options like metal or plastic drums, Paper IBCs are more affordable to manufacture. This directly reduces the packaging costs for businesses. Secondly, their lightweight nature significantly cuts down on transportation costs. Since they weigh less than many other types of containers, shipping companies can transport more units for the same price, saving on fuel and shipping fees. In terms of storage, Paper IBCs are often collapsible or stackable, which maximizes storage space and reduces the need for large storage facilities, further saving costs for businesses involved in the storage and handling of liquid products.

Reliable and Safe

Paper IBCs are made from FDA - approved materials, ensuring that they are suitable for food - grade applications. For example, the inner bags used in food - related packaging meet strict hygiene standards. They have also undergone rigorous drop tests, puncture tests, and leakage tests to ensure their integrity during transportation. Whether it's rough handling during loading and unloading or long - distance sea voyages, Paper IBCs can protect the liquids inside from damage, leakage, and contamination. This reliability makes them a trusted choice for transporting valuable and sensitive liquids, such as high - end wines or industrial chemicals that require strict quality control.

Environmentally Friendly

In an era where environmental concerns are at the forefront, Paper IBCs stand out as an eco - friendly option. They are made from renewable resources such as cardboard, which is derived from wood pulp. Additionally, they are fully recyclable, reducing the burden on landfills. When compared to non - biodegradable plastic containers, Paper IBCs produce significantly less environmental waste. Many industries are now prioritizing sustainable packaging solutions, and Paper IBCs fit perfectly into this trend, allowing companies to reduce their carbon footprint while still ensuring efficient liquid packaging.

Versatile in Use

Paper IBCs are highly versatile. Their design allows them to be used for a wide range of liquid viscosities and chemistries. They can handle the packaging of low - viscosity liquids like water - based surfactants as easily as high - viscosity industrial oils. This adaptability makes them suitable for different industries, from food and beverage to chemical manufacturing. Moreover, they can be customized in terms of size, capacity, and inner bag material to meet specific packaging requirements, making them a flexible choice for various liquid packaging needs.

Why Choose Topline as Your PAPER IBC Manufacturer?

? When it comes to selecting a PAPER IBC manufacturer, Topline stands out as a premier choice.

Advanced Production Technology

Topline is equipped with state - of - the - art production technology. Our manufacturing facilities are designed to produce high - quality Paper IBCs efficiently. We use the latest machinery and equipment to ensure that each Paper IBC meets the highest standards of quality. For example, our automated production lines can precisely cut and assemble the cardboard components, ensuring a perfect fit. The production process also allows for strict control over the thickness and strength of the cardboard and the inner bag materials, guaranteeing the durability and reliability of the final product.

Stringent Quality Control

Quality is at the heart of everything we do at Topline. We have a comprehensive quality control system in place. Each Paper IBC undergoes multiple quality checks during the production process. From the inspection of raw materials to the final product testing, we leave no stone unturned. Our quality control team is trained to detect even the slightest flaws. We conduct regular leak - tests on the inner bags and structural integrity tests on the cardboard exteriors. This dedication to quality ensures that our customers receive Paper IBCs that are not only safe and reliable but also meet or exceed industry standards.

Exceptional Customer Service

At Topline, we pride ourselves on providing exceptional customer service. Our team of experts is always ready to assist you, from the initial consultation to after - sales support. If you have any questions regarding the selection of the right Paper IBC for your specific needs, our customer service representatives are just a phone call or an email away. We also offer customization services, working closely with you to design and produce Paper IBCs that meet your unique requirements. After - sales, we are committed to addressing any issues promptly, ensuring a smooth and hassle - free experience for our customers.

Conclusion

In conclusion, Paper IBCs offer a plethora of advantages that make them an ideal choice for liquid packaging across multiple industries. Their cost - effectiveness, reliability, environmental friendliness, and versatility set them apart from traditional packaging options. Whether you are in the food industry, dealing with industrial oils, or handling non - hazardous liquid chemicals, Paper IBCs can meet your packaging needs efficiently.

When it comes to sourcing Paper IBCs, Topline stands as a reliable and professional PAPER IBC manufacturer. Our advanced production technology, stringent quality control, and exceptional customer service ensure that you receive the highest - quality Paper IBCs tailored to your requirements. Don't miss out on the opportunity to enhance your liquid packaging operations. Choose Paper IBCs and partner with Topline for all your liquid packaging needs.